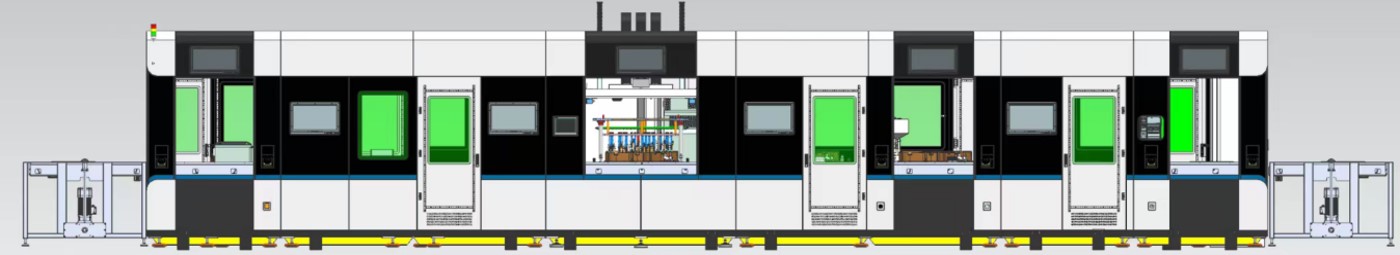

Huzhou, China - September 2025 - Huzhou Huazhuo Automation Equipment Co., Ltd. is honored to announce that its eighth K11 door panel automated assembly line, developed for a leading automotive interior parts manufacturer, has been successfully delivered and put into production in 2025.

After a month of intensive discussions, designs, production, assembly and commissioning, this customized production line was delivered on schedule and has officially entered the stable mass production stage. Since the technology was first introduced in 2023, Huazhuo's door panel automated assembly line has been continuously optimized, earning recognition from industry leaders and successfully applied in multiple large-scale projects.

Core technology: Functional connection triangle

The K11 door panel assembly line integrates three core automated processes - robot screw tightening, hot melt welding and automatic snap-fit installation. They together form the functional connection triangle of the car door structure, directly determining the strength, sealing performance and long-term durability of the car door.

Robot screwing - Under the guidance of a visual system, the robot automatically tights the screws to the precise hole positions and torque levels, ensuring consistent quality and efficiency.

Hot riveting and welding - Hot melt welding technology firmly bonds the door panel components, enhancing the integrity and stability of the structure.

The robot installs the snap fasteners - The snap fasteners are automatically classified by the vibrating plate and then precisely picked up and inserted in sequence by the robot, establishing a firm connection between the outer panel and the interior panel.

Customer value

1.By integrating these advanced processes, the K11 door panel production line can:

2.Enhance production efficiency and reduce labor.

3.Enhance product consistency and reduce defect rates.

4. Provide end users with more powerful structural performance and reliable sealing.

5. Flexible production capacity, capable of adapting to different vehicle models.

Committed to innovation

"The project not only marks the eighth K11 door panel assembly line we delivered this year, but also indicates that Huazhuo has taken another solid step forward in its mission to promote the automation process of the automotive interior industry," said a Huazhuo spokesperson. We are always committed to providing innovative, reliable and customer-centric solutions to help our partners achieve sustainable growth.

About Huazhuo Automation's Huzhou production base

Huazhuo was founded in Huzhou, China, and is dedicated to providing advanced plastic welding and automation equipment for automotive interior and exterior components. With over 12 years of industry experience, nearly 100 processing machines, a 2,000-square-meter production workshop, and an outstanding track record of more than 200 successful projects, Huazhuo continuously provides high-performance and customized solutions for global automakers.